Flake grade graphite products in diversified carbon contents, average particle size larger than 150 microns (100 mesh ASTM)

The Graflake product line is a natural crystalline graphite with an average particle size larger than 150 microns (100 mesh ASTM) and carbon ranging from 87% to 99.9%.

Graflake is produced from ore extracted from the mines of Pedra Azul and Salto da Divisa, both located in the north of the State of Minas Gerais, a region in which Nacional de Grafite holds the rights to exploit one of the world’s largest reserves of crystalline natural graphite.

Near each mine, Nacional de Grafite has a modern concentration plant, in which the graphite is separated from the impurities by mechanical concentration processes, preserving the original characteristics of graphite.

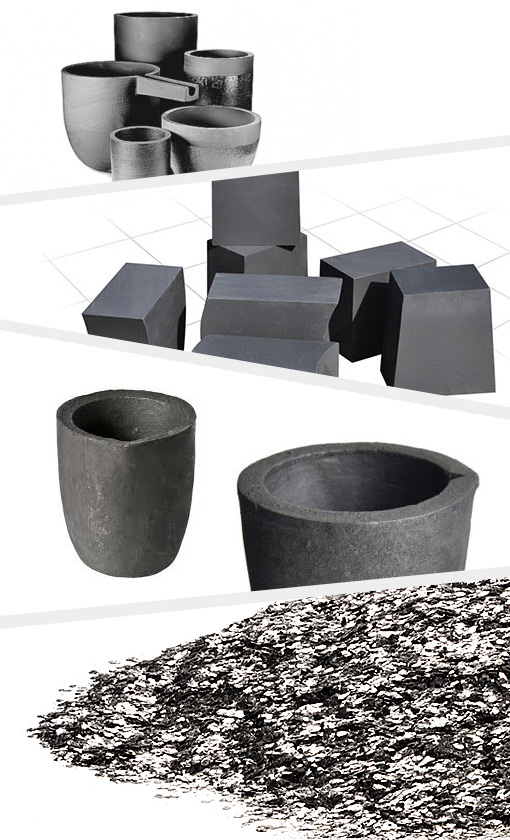

The Graflake line is the right solution for:

- Magnesia-Carbon Refractories;

- Alumina-carbon Refractories;

- Special refractories for continuous casting systems;

- Crucibles;

- Raw material for the production of expandable and expanded graphite.

Chemical Properties

| Products | Parameters | |||

| Carbon % | Ash % | Moisture % | ||

| Graflake 87100 | G | ≥ 87,0 | ≤ 13,0 | ≤ 0,3 |

| T | 90,0 | 10,0 | 0,1 | |

| Graflake 8780 | G | ≥ 87,0 | ≤ 13,0 | ≤ 0,3 |

| T | 90,3 | 9,7 | 0,2 | |

| Graflake 8860 | G | ≥ 88,0 | ≤ 12,0 | ≤ 0,3 |

| T | 91,0 | 9,0 | 0,2 | |

| Graflake 94140 | G | ≥ 94,0 | ≤ 6,0 | ≤ 0,3 |

| T | 95,1 | 4,9 | 0,1 | |

| Graflake 94140 di | G | ≥ 94,0 | ≤ 6,0 | ≤ 0,2 |

| T | 95,2 | 4,8 | 0,1 | |

| Graflake 9480 | G | ≥ 94,0 | ≤ 6,0 | ≤ 0,3 |

| T | 94,9 | 5,1 | 0,2 | |

| Graflake 9580 | G | ≥ 95,0 | ≤ 5,0 | ≤ 0,3 |

| T | 96,0 | 4,0 | 0,1 | |

| Graflake 98100 | G | ≥ 98,0 | ≤ 2,0 | ≤ 0,3 |

| T | 98,7 | 1,3 | 0,1 | |

| Graflake 9880 | G | ≥ 98,0 | ≤ 2,0 | ≤ 0,3 |

| T | 98,6 | 1,4 | 0,1 | |

| Graflake 9980 | G | ≥ 99,0 | ≤ 1,0 | ≤ 0,3 |

| T | 99,4 | 0,6 | 0,1 | |

| Graflake 9950 | G | ≥ 99,0 | ≤ 1,0 | ≤ 0,3 |

| T | 99,4 | 0,6 | 0,1 | |

| Graflake 99550 | G | ≥ 99,5 | ≤ 0,5 | ≤ 0,3 |

| T | 99,8 | 0,2 | 0,1 | |

Physical Properties

| Mesh size | Accumulated Retained in % | |||||||||||

| 30# | 35# | 40# | 50# | 60# | 70# | 80# | 100# | 140# | 200# | Bulk Density (g / cm³) | ||

| µm | 600 | 500 | 425 | 300 | 250 | 212 | 180 | 150 | 106 | 75 | ||

| Graflake 87100 | G | * | * | * | * | * | * | * | ≥ 80,0 | * | * | * |

| T | 09 | – | 4,8 | 18,6 | 33,8 | 51,3 | 68,7 | 86,1 | 95,9 | 98,2 | 0,56 | |

| Graflake 8780 | G | * | * | * | * | ≥ 60,0 | * | ≥ 85,0 | * | * | ≥ 97,0 | * |

| T | 8,4 | – | 30,0 | 62,4 | 76,5 | 84,8 | 90,0 | 94,6 | 98,1 | 98,9 | 0,52 | |

| Graflake 8860 | G | * | * | ≥ 25,0 | * | ≥ 80,0 | * | * | * | ≥ 97,0 | * | * |

| T | 10,8 | – | 39,0 | 72,4 | 85,5 | 91,8 | 95,3 | 97,4 | 98,7 | 99,7 | 0,51 | |

| Graflake 94140 | G | * | ≤ 7,0 | * | * | * | * | * | 10*60 | ≥ 60,0 | * | * |

| T | 0,4 | 0,8 | 2,3 | 8,5 | 15,2 | 25,6 | 36,3 | 52,9 | 69,4 | 81,5 | 0,49 | |

| Graflake 94140 di | G | * | ≤ 10,0 | * | * | ≥ 25,0 | * | * | * | ≥ 70,0 | * | * |

| T | 1,7 | 3,6 | 8,6 | 22,5 | 31,3 | 40,9 | 48,9 | 60,0 | 75,0 | 85,8 | 0,42 | |

| Graflake 9480 | G | * | * | * | * | * | * | ≥ 80,0 | * | * | * | * |

| T | 2,4 | – | 14,2 | 44,0 | 61,1 | 75,2 | 85,5 | 91,7 | 97,0 | 99,0 | 0,47 | |

| Graflake 9580 | G | * | * | * | * | * | * | ≥ 80,0 | * | * | * | * |

| T | 0,9 | – | 5,4 | 23,3 | 42,3 | 64,7 | 84,7 | 95,1 | 99,4 | 99,8 | 0,52 | |

| Graflake 98100 | G | * | * | * | * | * | * | * | ≥ 80,0 | * | * | * |

| T | * | – | 2,7 | 15,0 | 30,8 | 55,2 | 69,4 | 86,0 | 95,2 | 98,1 | 0,47 | |

| Graflake 9880 | G | * | * | * | * | * | * | ≥ 80,0 | * | * | * | * |

| T | 1,9 | – | 10,0 | 31,9 | 51,0 | 70,8 | 84,2 | 94,7 | 99,0 | 99,5 | 0,50 | |

| Graflake 9980 | G | * | * | * | * | * | * | ≥ 80,0 | * | * | * | * |

| T | 1,4 | – | 6,3 | 31,2 | 59,3 | 72,4 | 84,7 | 91,8 | 96,7 | 98,5 | 0,49 | |

| Graflake 9950 | G | * | * | * | ≥ 80,0 | * | * | * | * | * | * | * |

| T | 11,4 | – | 47,4 | 87,1 | 94,7 | 97,8 | 98,7 | 99,3 | 99,7 | 99,8 | 0,47 | |

| Graflake 99550 | G | * | * | * | ≥ 90,0 | * | * | * | * | * | * | * |

| T | 19,0 | – | 58,8 | 93,3 | 97,5 | 99,2 | 99,5 | 99,7 | 99,8 | 99,9 | 0,48 | |

| * = Not specified T = Typical value G = Guaranteed limits | ||||||||||||